Elektriese vragmotor kennis

Attention, Dump Truck Owners! Don’t Ignore the Daily Maintenance of Dump Trucks

Geplaas op deur Elektriese vragmotors

When the image of stortwas comes to mind, the initial impression is often one of a “dirt-covered” and filthy appearance. Truly, due to the nature of their working environment, stortwas are typically in a rather soiled state, and as a result, users frequently overlook the significance of daily cleaning and maintenance. This is a grave oversight. Maintaining a vehicle in top condition is of paramount importance, and stortwas are no exception. Vandag, the editor brings you in-depth knowledge regarding the maintenance of stortwas.

-

Given the challenging working conditions of stortwas, it is essential to wash the vehicles frequently. Not only does this prevent dirt accumulation but also helps to minimize potential bumps and scratches. Daarbenewens, maintaining a clean interior is crucial for the overall functionality and longevity of the vehicle.

-

During inclement weather such as rain and snow, it is imperative to ensure that the vehicle is parked in a secure location. This precaution helps evade potential hazards like mudslides and avalanches, safeguarding both the vehicle and its occupants.

-

It is highly recommended to grease the stortwa frequently when it is not in operation. Special attention should be given to the hydraulic cylinder, which requires regular greasing to ensure smooth and efficient functioning.

-

If the vehicle is utilized for transporting ores or similar materials, it is advisable to weld iron bars every 10 kilograms inside the compartment. This simple measure provides protection against compartment deformation due to the impact of heavy loads.

-

Any minor issues with the vehicle should be addressed promptly. Ignoring small problems can often lead to more significant and costly breakdowns in the long run.

Maintenance of dump trucks is very important

New Vehicle Inspection of Dump Trucks

-

Verify whether the oil quantity within the hydraulic oil tank is adequate. In cases where it is insufficient, add oil up to the stipulated quantity, adhering to the specified oil grade. Simultaneously, inspect for leaks in the manual control valve and the air circuit, as well as any potential oil leaks in the hydraulic system’s oil circuit.

-

Under no-load conditions, perform lifting tests in accordance with the operational procedures of the tilting mechanism for both lifting and lowering actions.

-

Throughout the lifting process, remain vigilant and check whether components such as the hydraulic cylinder, gear pump, control valve, and others are functioning properly. Pay close attention to any signs of sticking, erratic movement, bouncing, or abnormal noises during the hydraulic lifting operation.

-

After conducting 8-10 no-load lifting tests, if the performance is deemed normal and there are no signs of oil or gas leakage, it can be concluded that the tilting performance is satisfactory.

Beyond the basic maintenance and new vehicle inspection points mentioned above, there are several other critical aspects that stortwa owners and operators need to be cognizant of.

Regular inspection of the braking system is of utmost significance. The brakes of a stortwa undergo significant stress and wear due to the heavy loads they carry. Inspect the brake pads for excessive wear, check the brake fluid levels, and ensure the brake lines are free from leaks or damage. A malfunctioning braking system can lead to disastrous consequences on the road.

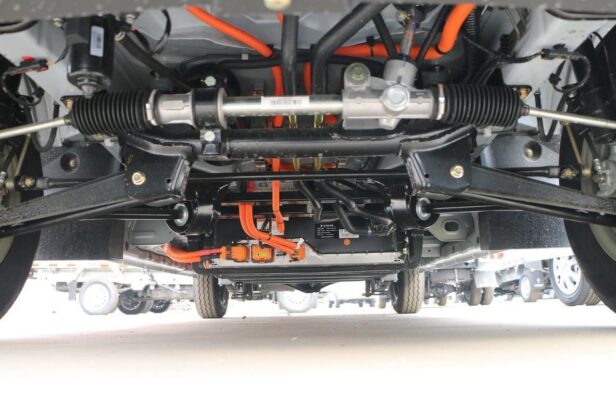

The suspension system also deserves close attention. The constant pounding and jolts endured by the stortwa during operation can take a toll on the suspension components. Inspect for signs of wear on shock absorbers, springs, and other suspension elements. Replace any worn-out parts promptly to maintain a smooth and stable ride.

The engine, being the heart of the vehicle, requires regular servicing. Change the engine oil and oil filter at the recommended intervals. Check the coolant levels and the condition of the belts and hoses. A well-maintained engine ensures optimal power output and fuel efficiency.

The electrical system should not be overlooked either. Inspect the battery terminals for corrosion, ensure the wiring harness is intact, and test the lights and other electrical accessories for proper functioning. Electrical faults can cause unexpected breakdowns and safety hazards.

In addition to the mechanical aspects, the tires of the stortwa play a vital role in its performance and safety. Regularly check the tire pressure to ensure it is within the recommended range. Inspect the tires for cuts, bulges, or uneven wear. Rotate the tires periodically to ensure even wear and extend their lifespan.

When it comes to maintenance schedules, it is essential to adhere to the manufacturer’s guidelines. Egter, depending on the intensity and nature of usage, it may be necessary to perform some maintenance tasks more frequently. Byvoorbeeld, if the stortwa operates in extremely dusty or corrosive environments, the air filter and fuel filter may need to be replaced more often to prevent impurities from entering the engine and causing damage.

Bowendien, maintaining detailed records of all maintenance activities is highly beneficial. This includes noting the dates of servicing, parts replaced, and any issues encountered. Such records not only help in tracking the vehicle’s maintenance history but also assist mechanics in diagnosing potential problems more accurately in the future.

It is also advisable for stortwa operators to undergo regular training on vehicle maintenance and safety procedures. This equips them with the knowledge and skills to identify potential problems early on and take appropriate corrective actions.

An example of the importance of proper maintenance can be seen in a case where a stortwa owner neglected to inspect the suspension regularly. Met verloop van tyd, a worn-out shock absorber led to instability during a loaded drive, resulting in a minor accident that not only caused damage to the vehicle but also led to delays in the delivery schedule and financial losses.

Another instance is when a driver ignored a slight leak in the hydraulic system. Eventually, the leak worsened, causing a complete failure of the lifting mechanism during an important delivery, causing significant disruption and additional repair costs.

Ter afsluiting, the daily maintenance of stortwas is not just a matter of routine but a crucial aspect that directly impacts the vehicle’s performance, veiligheid, and longevity. By being diligent in maintenance practices, addressing issues promptly, and adhering to recommended schedules and procedures, stortwa owners and operators can ensure reliable and efficient operation, minimize the risk of breakdowns and accidents, and ultimately save both time and money in the long run.

Verder, as technology continues to advance, new maintenance techniques and tools are emerging. It is essential for the industry to stay updated and adopt these innovations to enhance the maintenance standards of stortwas. Byvoorbeeld, the use of predictive maintenance systems that utilize sensors and data analytics to predict potential failures before they occur is becoming increasingly common.

In addition, the development of more durable and high-performance components can also contribute to reducing the maintenance requirements and increasing the overall reliability of stortwas. Egter, even with these advancements, the fundamental principles of regular inspection, timely servicing, and operator awareness remain unchanged.

In summary, the maintenance of stortwas is a complex but essential task that demands attention to detail, adherence to best practices, and a commitment to ensuring the highest standards of safety and performance. By doing so, die stortwa can continue to play its vital role in various industries, contributing to the smooth progress of construction, transportation, and other related activities.