With the widespread promotion and popularization of new energy electric vehicles, an increasing number of after-sales maintenance issues have surfaced before consumers. Among them, the maintenance cost of new energy electric vehicle batteries is the most prominent concern for people. There have always been questions like whether replacing the battery after driving the car for an extended period is more expensive than purchasing a new vehicle.

The cost of batteries for new energy electric vehicles is relatively high. Based on the market price in early 2019, the average battery cost approximately 1,200 yuan per kilowatt-hour considering the battery capacity. For instance, if a new energy vehicle is equipped with a 40-kilowatt-hour battery, this implies that the cost of the battery alone amounts to 48,000 yuan.

The state stipulates that the warranty period for the three power systems of new energy electric vehicles should be at least five years or 200,000 kilometers. Some vehicles even offer a warranty period of eight years or 300,000 kilometers, and certain car companies promise a lifetime warranty for the battery. That is to say, during the warranty period, the maintenance of the battery, motor, and electronic control system is complimentary. What consumers are most apprehensive about is the situation after the warranty period. If the battery truly malfunctions and it costs around 50,000 yuan to replace a battery pack, then it might indeed be a case of being able to afford the vehicle but not the repair.

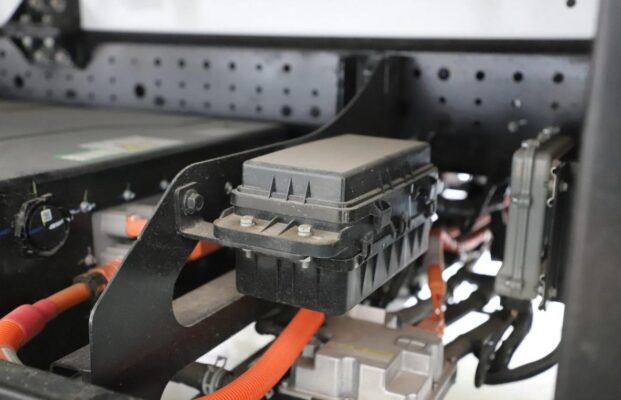

The battery pack is installed on the chassis of an electric van.

In reality, if the battery pack does break down, it is feasible to disassemble the battery pack and replace the battery cells individually. A 40-kilowatt-hour battery pack is actually composed of nearly 40 groups of batteries. If one of the small groups fails, it can be replaced separately. Generally, the repair cost is approximately two to three thousand yuan.

Here are the pictures of a new energy electric van’s battery after disassembly for everyone to view:

When opening the battery pack, more than 30 groups of battery cells can be observed. Each group is equipped with a temperature sensor and a voltage sensor. The sensors comprehensively transmit the signals to the battery management system (BMS), and the BMS then relays the information to the on-board computer.

A picture of a single battery cell. This battery cell can be replaced independently, but the brand and capacity of the battery should be consistent, and the voltage of the battery should align with that of other battery cells during installation.

The battery cells within the battery pack. Currently, most vehicles utilize the 18650 model of battery cells, which is the same model as those found in everyone’s laptops.

A close-up of the battery cells in the battery pack. The minimum voltage of each battery cell is approximately 3.5V and the maximum voltage is about 4.2V. Multiple battery cells are connected in parallel to form a battery pack.

Now, let’s explore some additional aspects and considerations related to the maintenance cost and technology of new energy vehicle batteries:

The development of battery technology is constantly evolving. Newer and more advanced battery chemistries and designs are emerging, which may not only increase the energy density and performance of the batteries but also potentially reduce their manufacturing and maintenance costs over time. This could lead to more affordable replacement options in the future.

The recycling and reuse of battery packs also play a significant role in reducing overall costs. As the number of electric vehicles on the road increases, the establishment of efficient battery recycling infrastructure becomes crucial. Recycled materials and components from old battery packs can be used to manufacture new batteries or other products, which can offset some of the costs associated with battery replacement.

The complexity of battery management systems also affects maintenance costs. Advanced BMS systems can better monitor and optimize the performance and health of the battery cells, extending their lifespan. However, the development and maintenance of these systems themselves also require investment and expertise.

The operating conditions and charging habits of the vehicle owner can have a substantial impact on battery longevity and maintenance costs. Frequent fast charging, extreme temperatures, and deep discharging can all accelerate battery degradation. Educating consumers on proper usage and charging practices can help prolong battery life and reduce the likelihood of premature failure.

Be to, the availability and cost of skilled technicians who are proficient in diagnosing and repairing battery issues can vary by region. This can influence the overall cost and accessibility of battery maintenance services.

As the market for new energy vehicles continues to grow and mature, economies of scale and technological advancements are likely to drive down the cost of batteries and their maintenance. However, it is essential for both manufacturers and consumers to stay informed and proactive in managing battery health to ensure the long-term affordability and sustainability of electric vehicle ownership.

In the future, we might also see innovations in battery leasing or subscription models, where instead of outright purchasing a battery, consumers pay a monthly fee for access to a maintained and updated battery pack. This could potentially shift the financial burden and risk associated with battery ownership.

Apibendrinant, while the maintenance cost of new energy vehicle batteries is a significant consideration currently, the landscape is constantly changing, and various factors are at play that could lead to more favorable and sustainable solutions in the years to come.