Electric Truck News

Precautions for long-term parking of new energy electric trucks

Posted on by Electric Trucks

In today’s rapidly evolving transportation landscape, the number of new energy electric trucks on the market is steadily increasing. These vehicles are playing an increasingly important role in the freight transportation industry, offering environmental benefits and operational efficiencies. However, unlike family cars, freight trucks are often subject to the fluctuations of freight source seasons. For instance, the first half of the year may be a slow season for freight, while after summer, with the surge in fast-moving consumer goods and the approaching major shopping festivals like Double Eleven, Double Twelve, and the New Year’s Shopping Festival in the second half of the year, the demand for freight trucks spikes. As a result, there are times when electric trucks may experience idle periods. Today, let’s delve into the precautions that need to be taken when electric trucks are parked for an extended period.

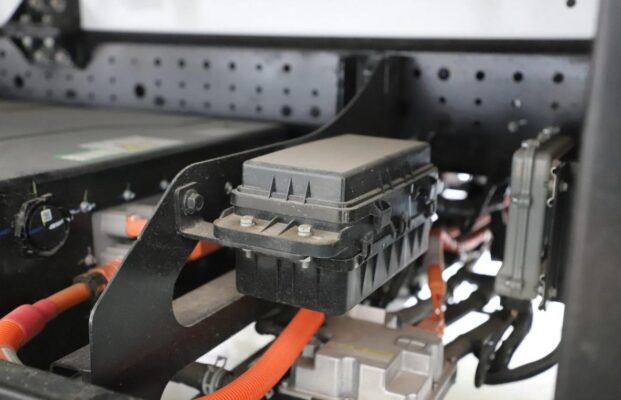

- Disconnect the negative pole of the small battery or turn off the power supply switch:

This is a crucial step to prevent the small battery from being in a state of long-term power loss, which could potentially cause damage to the battery. By disconnecting the negative pole or turning off the power supply switch, you can ensure that the small battery is not constantly draining power. This not only protects the battery but also makes it convenient for direct connection to the negative pole next time for normal operation. Otherwise, if the small battery loses all its power, it can be a cumbersome process to find and borrow connecting wires everywhere just to get the truck back on the road. Only after connecting the power can the vehicle operate normally again.

For example, imagine a truck that has been parked for a long time without disconnecting the small battery. Over time, the battery continues to drain power, even when the truck is not in use. This can lead to a situation where the battery is completely depleted, making it difficult to start the truck when needed. By taking the simple step of disconnecting the negative pole or turning off the power supply switch, you can avoid this potential problem and ensure a smoother start-up when the truck is back in service.

- Note that during the shutdown period, be sure to keep the power SOC above 60%:

When the power battery is not in use, there may still be a certain amount of power loss. To avoid causing a serious state of power loss that could potentially damage the battery or reduce its lifespan, it is essential to keep the battery’s state of charge (SOC) at a relatively high level. Keeping the SOC above 60% provides a buffer against unexpected power losses and ensures that the battery is in a better condition when it is needed again.

For instance, if the battery is left at a low SOC during long-term parking, it may lead to issues such as reduced battery capacity, difficulty in charging, or even damage to the battery cells. On the other hand, maintaining a higher SOC gives the battery a better chance of retaining its performance and longevity. This requires periodic checks on the battery’s charge level and, if necessary, topping up the charge to keep it above the recommended threshold.

- In northern cities in winter, pay attention to cold protection:

If the motor of the electric truck is water-cooled, special attention must be paid to the antifreeze. This is similar to ordinary cars. If the antifreeze does not meet the requirements, there is a risk of the pipelines being cracked by freezing. In cold winter climates, the low temperatures can pose significant challenges to the vehicle’s cooling system. Ensuring that the correct type and sufficient amount of antifreeze is in place is crucial to prevent damage to the motor and other components.

For example, if the antifreeze is not of the proper quality or concentration, it may not provide adequate protection against freezing. When water in the cooling system freezes, it expands, which can cause the pipelines to crack and lead to costly repairs. Regularly checking and maintaining the antifreeze level and quality is an important part of winterizing an electric truck, especially in northern regions where extremely cold temperatures are common.

- It is best to drive and charge every month:

To keep the power battery and the vehicle in the best condition, it is advisable to drive and charge the truck at least once a month. As the saying goes, cars are not afraid of being used but afraid of being parked. Regular use and charging help maintain the battery’s performance and prevent issues such as battery degradation or loss of capacity.

By driving the truck periodically, you allow the various components to operate and lubricate, ensuring that they remain in good working order. Charging the battery regularly helps maintain its charge level and also allows the battery management system to perform its diagnostic and maintenance functions. This not only extends the lifespan of the battery but also ensures that the truck is ready to go when needed.

For instance, if a truck is left parked for an extended period without being driven or charged, the battery may gradually lose its charge and capacity. This can lead to longer charging times and reduced driving range when the truck is finally put back into service. By following the recommendation of driving and charging monthly, you can keep the truck in optimal condition and avoid potential problems.

- Store the vehicle at a high place and do not let water or other liquids flood into the battery pack or high-voltage lines:

This is of utmost importance as electric vehicles are particularly vulnerable to water damage. Low-lying areas are prone to accumulate water, and electric trucks must be kept away from such locations. If water or other liquids flood into the battery pack or high-voltage lines, it can lead to serious consequences such as insulation issues, damage to the battery, and even the risk of fire.

For example, if a truck is parked in a low-lying area during a heavy rainstorm and water floods into the battery pack, it can cause short circuits, damage the battery cells, and render the truck inoperable. In severe cases, it can pose a safety hazard. Storing the vehicle at a high place reduces the risk of water damage and helps protect the valuable components of the electric truck.

- Park in a special place and it is not suitable to park outdoors for a long time:

During the storage period, it is recommended to park the truck in a dedicated or covered area rather than leaving it outdoors for an extended period. Outdoor parking exposes the vehicle to various elements such as sunlight, rain, wind, and dust, which can accelerate the deterioration of the vehicle’s exterior and components. Additionally, all vehicles should be powered on once a month and driven a certain distance to check that the clutch, brake, shifting, and other functions are in normal use.

For instance, if a truck is parked outdoors for a long time, the paint may fade, the tires may lose air, and the mechanical components may become rusty or damaged. By parking in a special place and periodically powering on and driving the truck, you can ensure that all the systems are functioning properly and detect any potential issues early on. This helps maintain the vehicle’s performance and reliability.

- If the vehicle is not used for a long time, it is recommended to perform a charge and discharge cycle for the small battery every three to six months:

Just like the power battery, the small battery also needs attention during long-term storage. Performing a charge and discharge cycle for the small battery every three to six months helps prevent damage to the battery in a state of long-term disuse. This process allows the battery to maintain its capacity and performance and reduces the risk of failure.

For example, if the small battery is left unused for an extended period without any charge and discharge cycles, it may lose its ability to hold a charge or may even fail completely. By following this recommendation, you can ensure that the small battery remains in good condition and is ready to support the vehicle’s electrical systems when needed.

In conclusion, proper precautions during long-term parking of new energy electric trucks are essential to maintain the vehicle’s performance, reliability, and safety. By following these guidelines, truck owners and operators can ensure that their vehicles are in good condition when they are needed again. This not only saves time and money on repairs but also contributes to the longevity and sustainability of these important transportation assets.