Te ite i te pae no te uira

Ten Taboos in Maintenance of Heavy Trucks

Tuuhia i ni'a i te na roto i te Te mau pereoo uira

Maintenance is an effective means to restore the performance of heavy trucks and prolong their service life. Tera râ,, during the actual operation, certain users and maintenance personnel adopt numerous incorrect practices, which adversely affect the normal utilization of heavy trucks.

- Avoid adding engine oil without changing it

Engine oil is indispensable for the operation of diesel engines, primarily fulfilling the functions of lubrication, cooling, and cleaning. Consequently, numerous drivers pay attention to checking the quantity of lubricating oil and add it as per the standard but neglect to inspect the quality of the lubricating oil and replace deteriorated engine oil. This leads to some moving components of the engine constantly operating in a suboptimal lubrication environment, thereby accelerating the wear of each part. Ordinarily, the loss of engine oil is not substantial, but it is prone to contamination, thereby losing its capacity to safeguard the diesel engine. During the operation of the diesel engine, a multitude of contaminants such as soot, carbon deposits, and scale resulting from incomplete combustion of the fuel enter the engine oil. For new or overhauled machinery, there are more impurities following the test run. If it is put into use merely by adding but not changing the oil, it is highly likely to give rise to unexpected incidents like the burning of the bearing bush and seizure of the bearing. Te tahi atu â mau mea, even when the engine oil is replaced, some drivers, due to a lack of maintenance experience or for convenience, fail to thoroughly clean the oil passage during the replacement process, leaving mechanical impurities remaining in the oil pan and oil passage.

Let’s consider a scenario where a heavy truck is constantly operating in harsh conditions, with frequent long-haul trips and heavy loads. The engine oil is exposed to extreme temperatures and high levels of stress. If the oil is not changed regularly and the quality is not inspected, the contaminants can accumulate rapidly, causing significant damage to the engine components and reducing the engine’s efficiency and lifespan.

- Avoid misusing and randomly applying grease

(1) Applying grease on the cylinder gasket. Grease is a commonly utilized lubricant in engineering machinery repair, capable of playing the roles of lubrication and sealing. Hence, some repairmen apply a layer of grease on the cylinder gasket during installation, believing that this can enhance the sealing performance of the diesel engine. Little do they realize that such an action adversely affects the operational performance of the diesel engine. The cylinder gasket serves as the most critical seal between the cylinder block and the cylinder head of a diesel engine. It not only seals the high-temperature and high-pressure gas generated within the cylinder but also seals the cooling water and lubricating oil within the cylinder head and the cylinder block. Therefore, particular attention should be given to its sealing quality during disassembly and assembly of the cylinder gasket. If grease is applied on the cylinder gasket during installation, when the cylinder head bolts are tightened, a portion of the grease will be squeezed into the cylinder water passage and oil passage, and the grease remaining between the cylinder gaskets will, when the cylinder is in operation, due to the influence of high temperatures, partially flow into the cylinder for combustion, and the other portion will remain on the joint surface between the cylinder block and the cylinder head, creating a gap between the cylinder gasket, the cylinder head, and the body plane. High-temperature and high-pressure gas can readily impact the cylinder gasket from this point, damaging the cylinder gasket and causing air leakage. Hau atu â, grease will also generate carbon deposits when exposed to high temperatures for an extended period, causing the cylinder gasket to age and deteriorate prematurely. Thus, do not apply grease when installing the cylinder gasket.

(2) Applying grease on tire nuts. To facilitate the tightening of nuts and prevent rusting, many repairmen apply oil on the bolt and nut of the tire. In actuality, this constitutes an incorrect practice. Since the tire nut, once tightened, possesses the characteristic of self-locking due to the smaller helix angle of the thread compared to the equivalent friction angle between the threads. In a given bolt connection, the helix angle remains a fixed value, while the equivalent friction angle varies with the friction state between the threads. Evidently, after applying oil, the equivalent friction angle between the threads decreases, and the self-locking performance of the bolt connection deteriorates. Therefore, never apply grease or drip lubricating oil on the bolts and nuts of the tire. Doing so will instead loosen the nuts and even potentially lead to accidents.

Imagine a heavy truck traveling at high speed on a busy highway. If the tire nuts are loosened due to the incorrect application of grease, it can result in a tire blowout, causing a serious accident and posing a significant threat to the safety of the driver and other road users.

- Avoid installing new cylinder liners and pistons without selection

When replacing the cylinder liners and pistons, it is wrongly assumed that the new cylinder liners and pistons are standard parts and are interchangeable, and can be used directly upon installation. In fact, the sizes of cylinder liners and pistons have specific tolerance ranges. For instance, if the cylinder liner of the largest size is paired with the piston of the smallest size, the fit clearance will be overly large, resulting in weak compression and difficulties in starting. Therefore, during replacement, it is essential to verify the size grouping codes of the standard cylinder liner and piston. The cylinder liner and piston utilized must have the same size grouping code as the standard cylinder liner. Only in this manner can the standard fit clearance between the two be ensured. Te tahi atu â mau mea, when each cylinder is equipped with the cylinder liner and piston of the same grouping code, attention should also be directed towards checking the cylinder-piston clearance prior to installation. To guarantee the assembly standard, a test should also be conducted before installation to prevent the installation of counterfeit and inferior defective products.

- Avoid not checking the travel allowance of the plunger

In the testing of the plunger fuel injection pump, many maintenance personnel fail to pay heed to checking the travel allowance of the plunger. The so-called travel allowance of the plunger refers to the amount of movement that the plunger can continue to ascend after being pushed to the top dead center by the cam on the camshaft. After adjusting the start time of fuel supply, the reason for checking the travel allowance is that the travel allowance of the plunger is correlated with the wear of the plunger and the sleeve. Once the plunger and the sleeve are worn, the plunger needs to ascend for a longer section before initiating fuel supply, thereby delaying the start time of fuel supply. When the adjusting bolt is unscrewed or a thicker adjusting pad or gasket is replaced, the lowest position of the plunger moves upward, reducing the travel allowance of the plunger. Hence, when maintaining and debugging the fuel injection pump, this travel allowance should be inspected first to determine whether the fuel injection pump is still adjustable. During the inspection, the following distinct methods should be adopted based on the different structures of the fuel injection pump: a) Rotate the camshaft, push the plunger to the top dead center, remove the fuel outlet valve and the valve seat, and measure using a depth vernier caliper. b) After pushing the plunger to the top dead center, pry the spring seat of the plunger spring with a screwdriver to raise the plunger to the highest point. Then insert a feeler gauge between the lower plane of the plunger and the adjusting bolt of the tappet for measurement. The standard travel allowance of the plunger is approximately 1.5mm, and the limit travel allowance after wear should not be less than 0.5mm.

- Avoid inaccurate measurement of cylinder clearance

When measuring the cylinder clearance, the measurement is erroneously conducted not in the direction perpendicular to the piston pin hole at the piston skirt but in other directions. The structural characteristic of the aluminum alloy piston is that it is smaller at the top and larger at the bottom, forming a conical shape, and the local section is oval. As a result, the cylinder clearance along the circumferential direction is unequal. During measurement, it is stipulated that the clearance in the direction of the long axis of the ellipse is the criterion, that is, the clearance perpendicular to the piston pin hole at the piston skirt is measured. This measurement approach is more convenient and accurate. Furthermore, in the reciprocating motion, the direction perpendicular to the piston pin hole at the piston skirt is subjected to greater wear due to the action of lateral pressure. Therefore, when measuring the cylinder clearance, the measurement should be performed in the direction perpendicular to the piston pin hole at the piston skirt.

- Avoid heating the piston with an open flame

Since the piston and the piston pin are interference fits, when installing the piston pin, the piston needs to be heated for expansion. At this juncture, some maintenance personnel directly heat the piston over an open flame. This practice is highly incorrect as the piston has uneven thickness in each part, and the degree of thermal expansion and contraction will vary. Heating with an open flame causes uneven heating of the piston and readily leads to deformation; the piston surface will also be adhered with carbon ash, reducing the piston’s service life. If the piston cools naturally after reaching a certain temperature, its metallographic structure will be compromised and its wear resistance will be significantly diminished, and its service life will also be considerably shortened. When installing the piston pin, the piston can be uniformly heated in hot oil to enable it to expand gradually. Avoid direct heating with an open flame.

- Avoid grinding the bearing bush with emery cloth

For some inexperienced repairmen, bearing bush repair poses a significant challenge. As it is difficult to master the scraping technique of the bearing bush, achieving the technical requirements for the bearing bush becomes arduous. For this reason, when some individuals replace the bearing bush, in an attempt to increase the contact area between the bearing bush and the crankshaft, they resort to using emery cloth grinding instead of scraping the bearing bush. This approach is highly undesirable in actual maintenance since the abrasive particles on the emery cloth are harder while the bearing bush alloy is softer. Thus, during grinding, the abrasive particles can easily embed within the alloy. When the diesel engine is operational, this will accelerate the wear of the journal and shorten the service life of the crankshaft.

- Avoid tightening bolts too tightly

During the disassembly and assembly process of construction machinery, the bolts in numerous parts have specified torque requirements, such as the transmission case, cylinder head, tire, connecting rod, and front axle. The tightening torque is explicitly stipulated in the manual and must not be arbitrarily altered. Tera râ,, many users mistakenly believe that a tighter fit is safer, but overly tight tightening can cause the screws or bolts to fracture and may also trigger malfunctions due to thread slippage.

- Avoid too high tire pressure

The inflation pressure of the tires of wheeled construction machinery is a crucial factor determining its service life and working efficiency. Both excessively high and excessively low tire pressure impact its lifespan and are detrimental to safe driving, particularly in hot summers. The scientific inflation standard should be as follows: Based on the standard tire pressure, with the variation of temperature, the tire pressure should be slightly adjusted. For instance, it should be 5% – 7% lower in summer compared to winter. Considering the high temperature in summer, the gas is heated and the pressure rises. Conversely, in winter, it must reach the standard pressure or be marginally lower.

- Avoid adding cold water suddenly when the water tank boils

Overload operation of the engine, inadequate heat dissipation, or a shortage of water in the water tank can cause the water tank to boil. At such times, if cold water is added immediately, it can result in cracks in the cylinder head and the cylinder block. Therefore, upon discovering that the water tank is boiling during use, immediate emergency measures should be implemented to halt the operation and allow the cooling water of the diesel engine to cool naturally.

I teie nei, let’s explore some additional maintenance considerations for heavy trucks:

Regular inspection of the braking system is of paramount importance. This includes checking the brake pads, discs, drums, and the condition of the brake fluid. Worn brake components can significantly compromise the truck’s stopping power, especially when carrying heavy loads.

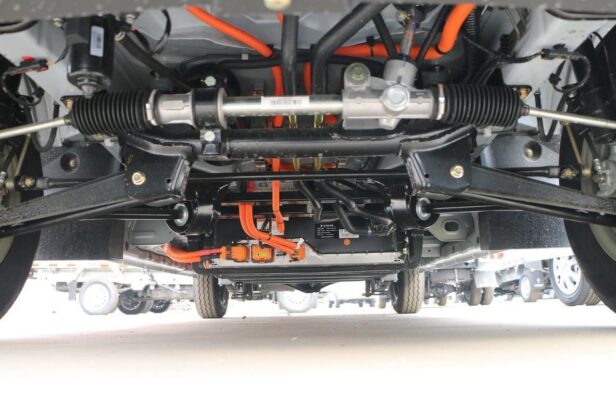

The suspension system also requires frequent attention. Inspecting the shock absorbers, leaf springs, and airbags for damage or wear helps ensure a smooth ride and proper weight distribution.

Electrical systems, such as the battery, alternator, and wiring, should be checked for proper functioning. Faulty electrical components can lead to starting problems, electrical shorts, and issues with the truck’s various electronic systems.

The exhaust system, including the muffler and catalytic converter, should be inspected for leaks or damage. A malfunctioning exhaust system can affect engine performance and emissions.

It’s also beneficial to establish a comprehensive maintenance schedule and keep detailed records of all maintenance activities. This helps in tracking the truck’s maintenance history, identifying recurring issues, and scheduling preventive maintenance.

In addition, training for maintenance personnel to stay updated with the latest maintenance techniques and best practices specific to heavy trucks is essential. This ensures that maintenance is carried out correctly and efficiently, minimizing the risk of breakdowns and maximizing the truck’s operational uptime.

Finally, using high-quality replacement parts and fluids that are recommended by the manufacturer is crucial for the reliable performance and longevity of the heavy truck.

Ei faaotiraa, by avoiding these common maintenance taboos and implementing proper maintenance practices, heavy truck owners and operators can ensure the safety, reliability, and longevity of their vehicles, reducing downtime and operating costs in the long run.